Home > Products > Blow Molding Machine > Full Automatic Apollo 200L Double L-Rings Drum Blow Molding Machine

Full Automatic Apollo 200L Double L-Rings Drum Blow Molding Machine

Technical Data for Blow Molding DM260General Issues volume of product: single cavity 260 L weight 33 ton output :20 pcs/hClamping UnitPrinciple: bi-direction synchronous clamping device with double axisLinear roller guidance horizontal (HIWIN)Clamping force: 750KNMold platens H x W: 1500 x 1000 ......

Send Inquiry

Product Description

Technical Data for Blow Molding DM260

General Issues

volume of product: single cavity 260 L

weight 33 ton

output :20 pcs/h

Clamping Unit

Principle: bi-direction synchronous clamping device with double axis

Linear roller guidance horizontal (HIWIN)

Clamping force: 750KN

Mold platens H x W: 1500 x 1000 mm

Distance between the platens: 750-1750 mm

Clamping unit stroke:1000 mm

Die Head

Type of die head: accumulator. With Ceramic heater

Max. storage volume: 20L

100 point WDS system controller

Power of heating: 52 KW

Extruder system

Screw diameter: 120/30D

Nitride treatment barrel and screw.

Plasticizing efficiency: 400kg/h (HDPE)

AC motor drive: 132KW

Cooling by five cooling fans.

Blow System(optional)

Blow system mounted on linear guide under mold

Height adjustment mechanism 250 mm

Blow pin up/down stroke: 150 mm, controlled by hydraulic cylinder.

Parison close

Mechanical adjustment for left and right

Take out system

Take out stroke 1000mm

Adopt Linear Guide and Synchronous belt transmission of motor to advance and retreat

Gripper with the function :auto cooling water

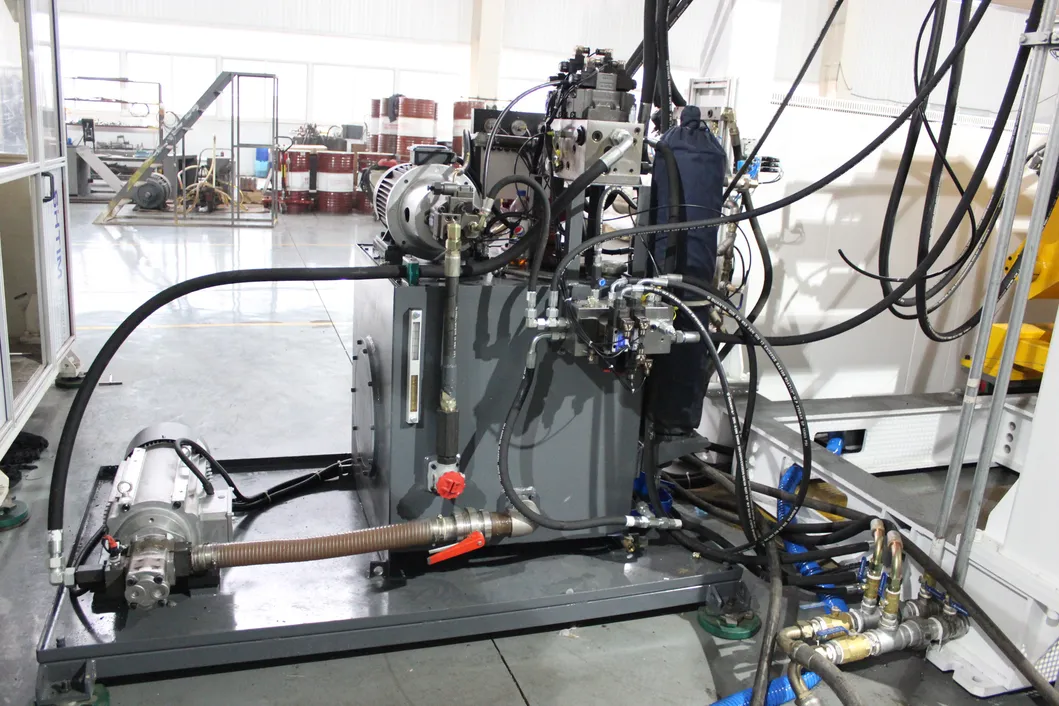

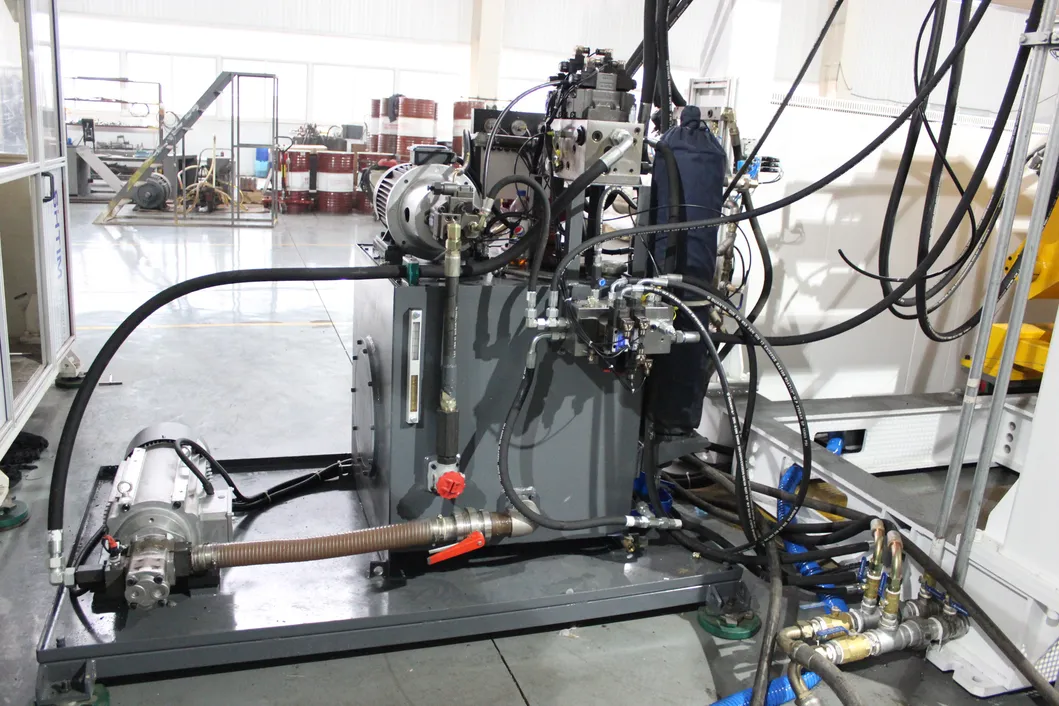

Servo Hydraulic System

Servo system REXROTH Servo Pump (200L)+ Servo Motor (22KW) Or DAIKIN brand

Hydraulic valves: YUKEN

Oil Temperature sensor showing the screen

Motor power: 22 KW+7.5KW

Servo valve:REXROTH

Pneumatic System

Pneumatic cylinders AIRTEC

Pneumatic valves : AIRTC

Max. pressure of gauge: 10 bar

Air consumptions: 3 m3/min

Control System

Control System: B&R

Servo WDS control system: B&R 100 points

Total rated power: 250 KW

Average energy consumption: 110 KW

Main components (Air switch, Contactor): SCHNEIDER ; intermediate relay: SCHNEIDER

Servo Driver: DAIKIN

for more informations, pls visit web: kingsmantech.en.made-in-china.com

KINGSMAN Company is the leadership of Extrusion blow moulding machine manufacturer Which had long-Term cooperation with KUATEX TEXTRON company from year 2010-2013 for 6 layer fuel tank machine.

KINGSMAN Company is espeicalized in Automatic Blow Moulding machine with High production.and now focus on Servo hydraulic machine for energy saving.

General Issues

volume of product: single cavity 260 L

weight 33 ton

output :20 pcs/h

Clamping Unit

Principle: bi-direction synchronous clamping device with double axis

Linear roller guidance horizontal (HIWIN)

Clamping force: 750KN

Mold platens H x W: 1500 x 1000 mm

Distance between the platens: 750-1750 mm

Clamping unit stroke:1000 mm

Die Head

Type of die head: accumulator. With Ceramic heater

Max. storage volume: 20L

100 point WDS system controller

Power of heating: 52 KW

Extruder system

Screw diameter: 120/30D

Nitride treatment barrel and screw.

Plasticizing efficiency: 400kg/h (HDPE)

AC motor drive: 132KW

Cooling by five cooling fans.

Blow System(optional)

Blow system mounted on linear guide under mold

Height adjustment mechanism 250 mm

Blow pin up/down stroke: 150 mm, controlled by hydraulic cylinder.

Parison close

Mechanical adjustment for left and right

Take out system

Take out stroke 1000mm

Adopt Linear Guide and Synchronous belt transmission of motor to advance and retreat

Gripper with the function :auto cooling water

Servo Hydraulic System

Servo system REXROTH Servo Pump (200L)+ Servo Motor (22KW) Or DAIKIN brand

Hydraulic valves: YUKEN

Oil Temperature sensor showing the screen

Motor power: 22 KW+7.5KW

Servo valve:REXROTH

Pneumatic System

Pneumatic cylinders AIRTEC

Pneumatic valves : AIRTC

Max. pressure of gauge: 10 bar

Air consumptions: 3 m3/min

Control System

Control System: B&R

Servo WDS control system: B&R 100 points

Total rated power: 250 KW

Average energy consumption: 110 KW

Main components (Air switch, Contactor): SCHNEIDER ; intermediate relay: SCHNEIDER

Servo Driver: DAIKIN

for more informations, pls visit web: kingsmantech.en.made-in-china.com

KINGSMAN Company is the leadership of Extrusion blow moulding machine manufacturer Which had long-Term cooperation with KUATEX TEXTRON company from year 2010-2013 for 6 layer fuel tank machine.

KINGSMAN Company is espeicalized in Automatic Blow Moulding machine with High production.and now focus on Servo hydraulic machine for energy saving.

Related Category

Plastic Machinery

Woodworking Machinery

Blow Molding Machine

Plastic Recycling Machine

Injection Molding Machine

Send Inquiry

Please Feel free to give your inquiry in the form below. We will reply you in 24 hours.